CNC vertical lathe milling center series

- Commodity name: CNC vertical lathe milling center series

- Product Description

-

Brand Heritage

The company has a rich and diverse product matrix. Its series of products are not only widely used in the domestic market, but have also received high praise from the engineering machinery manufacturing industry, automotive industry, aerospace field, and general parts processing industries. They are exported to international markets including Europe, America, South Korea, Russia, Australia, India, and Saudi Arabia.

Main Parameters

VL1250-ATC Name Unit Parameter Worktable Diameter mm φ1250 Maximum Swing Diameter mm φ1600 Maximum Turning Diameter mm φ1350 Maximum Workpiece Height mm 1200 Saddle Horizontal Travel (X-axis) mm -100+875 Slide Vertical Travel (Z-axis) mm 900 Ram Travel (Ram Vertical Travel) mm 800 Hydraulic Self-centering Solid Chuck

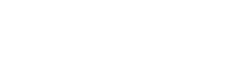

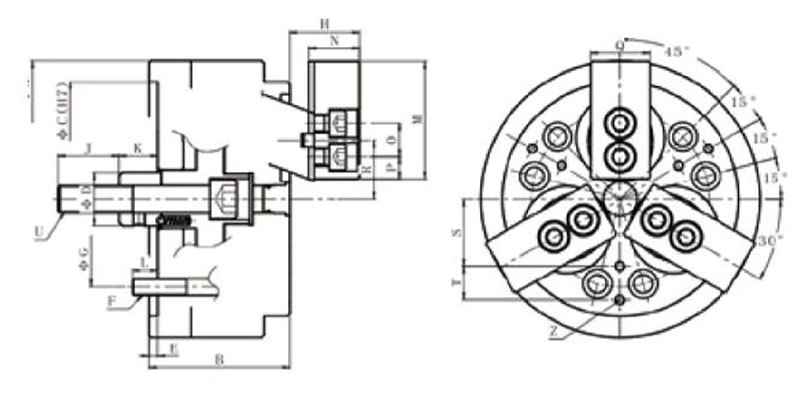

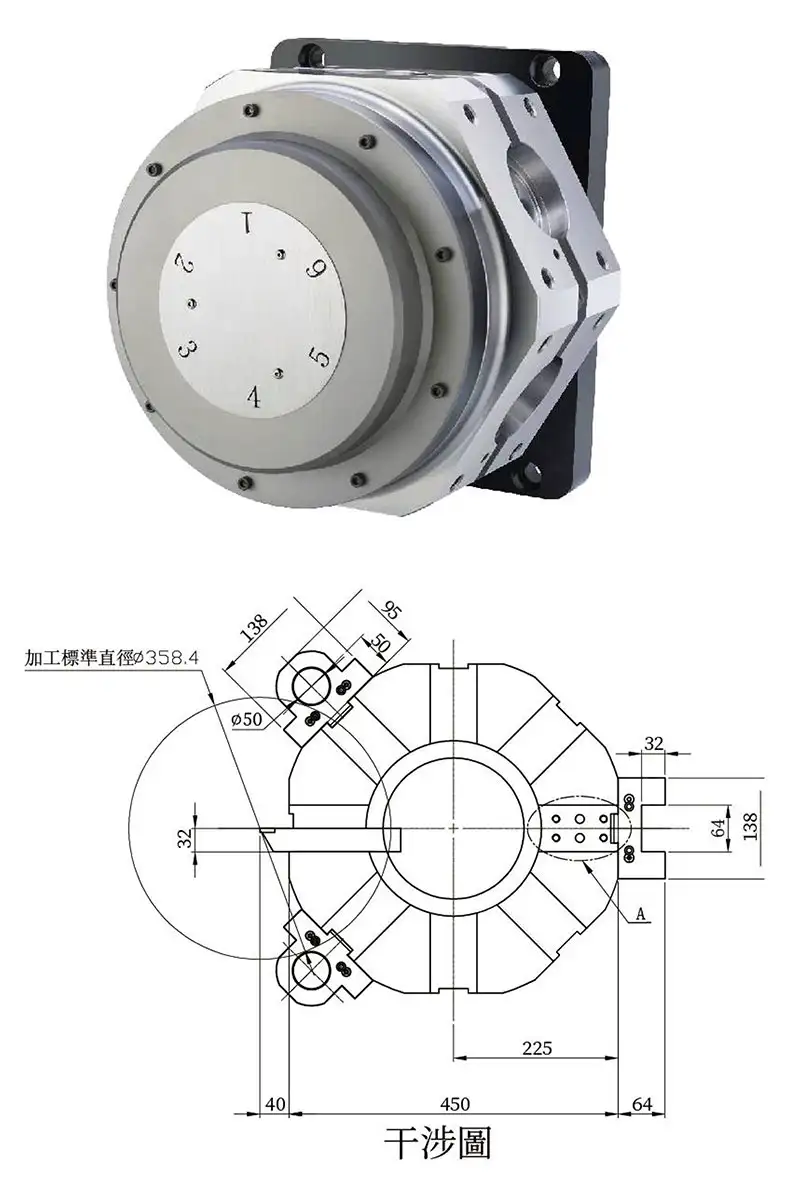

Optional Rear Pull-type Angled Column Chuck Size Options: 12/15/18/21/24/32 Jaw Options: 3/4/5/6 Customizable Workholding Fixtures Available Hydraulic/Servo Turret

Type A Series Type E Series

Station Options: 4/5/6/8/10/12

Type Options:

1. Vertical Tool Post (4/5/6)

2. Power Tool Post (12)

3. Horizontal Tool Post (8/12)

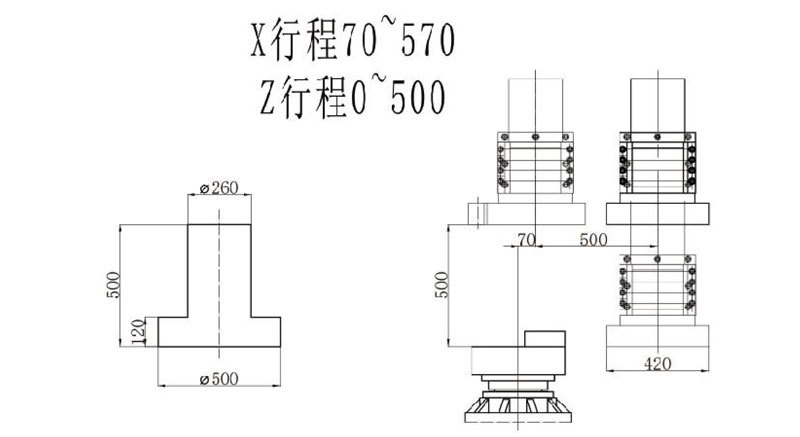

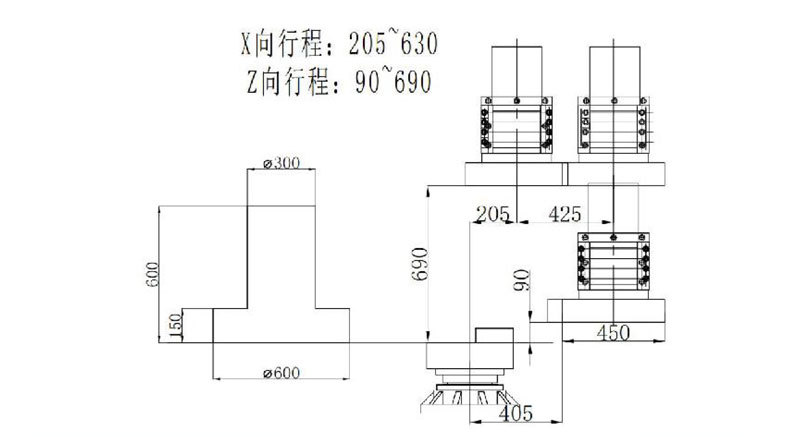

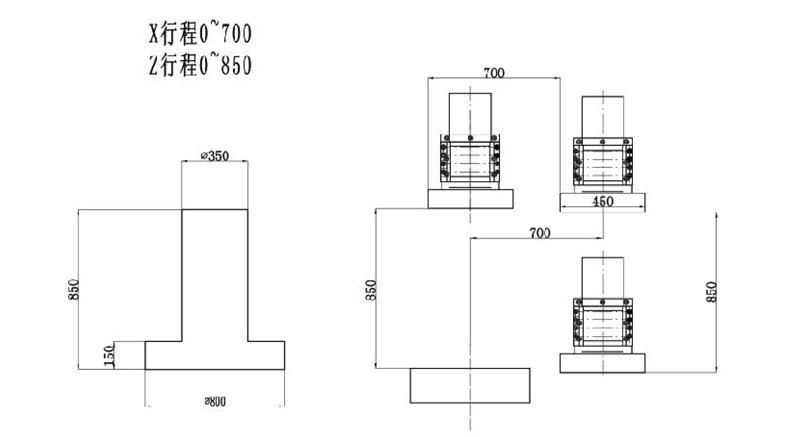

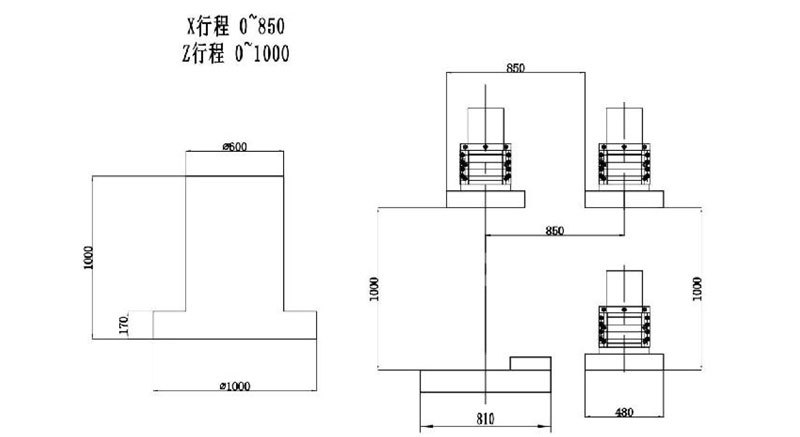

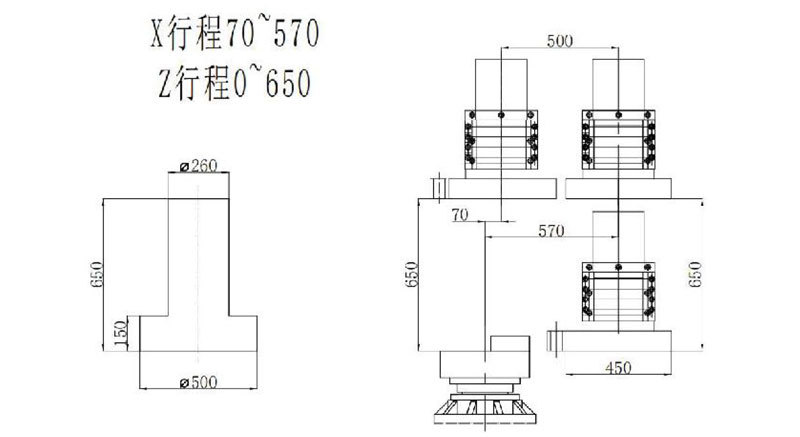

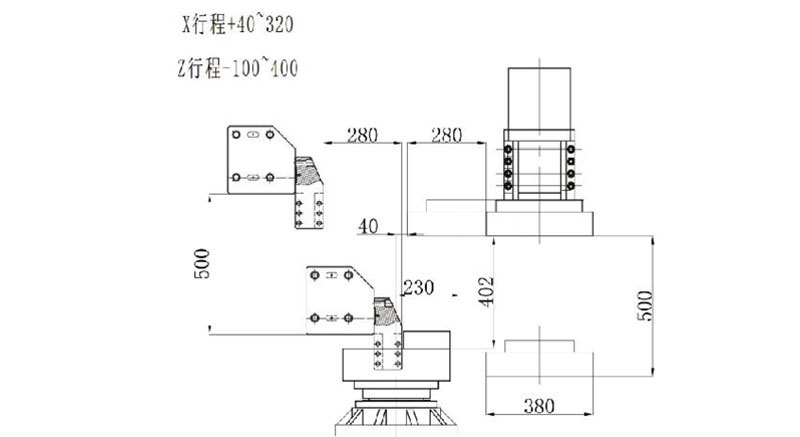

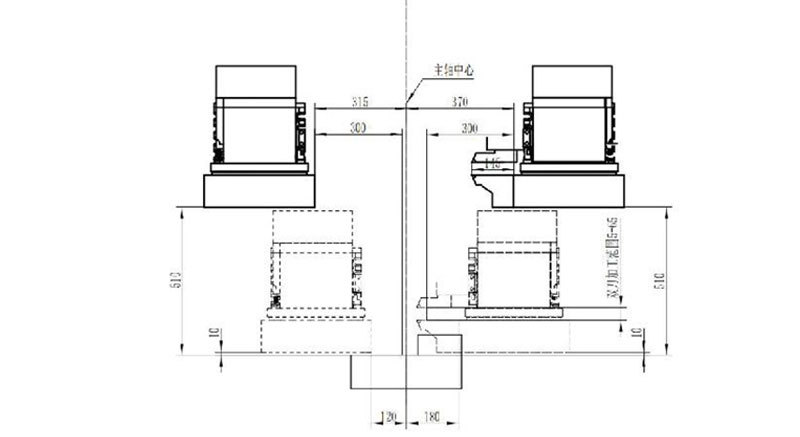

Standard Accessories Optional Accessories Complete Protective Sheet Metal Intelligent Robot Arm ABB/Fanuc/KUKA Hydraulic Three-Jaw Chuck and Rotary Cylinder Hydraulic Chuck and Hydraulic Rotary Cylinder Hydraulic Chuck Soft Jaws Hydraulic Chuck Hard Jaws Hydraulic Chuck Foot Switch Hydraulic Chuck High/Low Pressure Switching Device Hydraulic Unit Manual Worktable with Four Sets of Jaws Automatic Lubrication System Spindle Motor Power Upgrade Work Light Voltage Stabilizer Three-Color Warning Light Oil-Water Separator Workpiece Counter Tool Post Cutting Fluid System Custom Tool Post or Additional Parts Cutting Fluid Tank and Machine Flushing System Oil Mist Collector Electrical Cabinet Air Conditioner Extended Z-axis Travel Hand Tool Box Column Heightening Foundation Blocks High-Pressure Water Outlet for Tool Post Chain Plate Chip Conveyor Power Tool Spindle Two-Speed Gearbox Chip Cart Scraper Type Chip Conveyor Operation and Maintenance Manual Workpiece Test Machining Fixture Design Turnkey Project Solution Turret Travel Diagram (Maximum Machining Profile Diagram)

VTC50

VTC60

VTC80

VTC80A

VTC100A

CK60

CK525

KD500

Name Specifications Unit VTC450 VTC50 VTC60 VTC80 VTC80A Travel X-axis Travel mm 350 500 425 700 670 Z-axis Travel mm 0-700 0-500 90-690 0-850 170-1020 Processing Capacity Maximum Swing Diameter mm

φ650

φ650

φ650

φ850φ1000 Maximum Turning Diameter (Horizontal Tool Post) mm φ450 φ500 φ600 φ800 φ800 Maximum Turning Diameter (Vertical Tool Post) mm φ600 φ600 φ850 φ1000 Maximum Turning Height mm 700 500 600 850 850 Spindle Speed rpm 100-1000 100-1000 100-1000 100-800 100-800 Spindle Motor Power Kw 15 18.5 18.5 22 22 Shaft Diameter mm φ130 φ130 φ160 φ160 φ180 Hydraulic Chuck + Tool Post Chuck Type Three-jaw Hydraulic Chuck Chuck Specification Inch 15" 15" 21" 24" 24/32" Turret Stations Horizontal Eight-station Horizontal Eight-station Horizontal Eight-station Horizontal Eight-station Horizontal Eight-station Guideway/Lead Screw X-axis Roller Linear Guideway 2 pcs, 35mm wide 2 pcs, 45mm wide 2 pcs, 45mm wide 2 pcs, 45mm wide 2 pcs, 45mm wide Z-axis Roller Linear Guideway 2 pcs, 45mm wide 2 pcs, 45mm wide 2 pcs, 55mm wide 2 pcs, 55mm wide 2 pcs, 55mm wide X/Z Ball Screw Pair mm Ø40 Ø40/040 Ø40/050 Ø40/050 040/050 CNC System Standard System Configuration GSK GSK GSK GSK GSK Display, Chinese and English Display √ RS-232 Transmission Interface and USB Interface √ X-axis Motor Torque NM 10 10 18 15 18 Y-axis Motor Torque NM / / / / / Z-axis Motor Torque NM 22 22 30 22 30 Cutting Coolant System Cooling Motor W 450+750 450+750 450+750 750+1200 750+1200 Pump Output m³/h 4 4 4 4 4 Automatic Chip Conveyor √ Electrical Cabinet Air Conditioning √ Factory Accuracy Repeat Positioning Accuracy mm 0.005 0.005 0.005 0.007 0.007 Positioning Accuracy mm 0.008 0.008 0.008 0.01 0.01 Minimum Positioning Unit mm 0.001 0.001 0.001 0.001 0.001 Power Requirements Power Supply 3-AC 380V50Hz±5% The machine has leakage and power failure protection √ Three-color indicator light for machine operating status √ The machine can operate stably for a long time under the following conditions Ambient temperature 5~38, ambient humidity <85% The machine noise meets national standards √ Weight and Dimensions

(Based on actual shipment measurement)Overall Dimensions [Length*Width*Height](approx.) mm 1430*1995*2750 2330*2100*2800 2200*2000*3050 2500*2100*3300 2600*2200*3650 Weight (approx.) T 4 5.5 7.5 9 9.5 Remarks *The equipment adopts fully enclosed protection, and the protection device is safe and reliable, and should comply with GB/T15760-1995 General Technical Regulations for Safety Protection of Metal Cutting Machine Tools.

*Configure various hydraulic, pneumatic, and water pipe direction markings, mark the operating range of various instruments, and mark the grade of the medium used.VTC100A CK60 CK80 CK100 CK525 CK527 KD500 KD800 850 500 580 580 280 400 300 450 0-1000 150-800 50-720 50-850 500 600 500 160-660 φ1250 φ650 φ800 φ1000 φ750 φ750 φ650 φ950 φ1000 φ500 φ550 φ700 φ500 φ800 φ1250 φ600 φ750 φ1000 1000 650 670 800 500 600 500 500 100-800 100-1000 100-1000 100-800 100-1000 100-1000 100-1000 100-1000 22 18.5 22 22 18.5 22 30 22 φ200 φ140 φ160 φ160 φ160 φ160 φ160 φ180 Three-jaw Hydraulic Chuck 32" 18" 24" 24" 21" 21" 15" 24" Horizontal Eight-station Vertical Four-station Vertical Four-station Vertical Four-station Eight-station + Tool Changer Horizontal Eight-station Horizontal Eight-station Horizontal Eight-station 2 pcs, 55mm wide 2 pcs, Rectangular Hard Guideway 2 pcs, Rectangular Hard Guideway 2 pcs, Rectangular Hard Guideway 4 pcs, 45mm wide 2 pcs, 45mm wide 3 pcs, 55mm wide 2 pcs, Rectangular Hard Guideway 2 pcs, 55mm wide 2 pcs, Rectangular Hard Guideway 2 pcs, Rectangular Hard Guideway 2 pcs, Rectangular Hard Guideway 4 pcs, 45mm wide 2 pcs, 55mm wide 4 pcs, 55mm wide 4 pcs, Rectangular Hard Guideway Ø50/050 040/040 Ø40/050 040/050 Ø40/040 040/050 X/Z:050/050 X/Z:050/050 GSK GSK GSK GSK KND 2000 KND 2000 KND K2000 KND K2000 √ √ 22 10 15 15 15 15 18 23 / / / / / / 7 / 30 22 18 18 15 30 22 23 750+1200 450+750 750+1200 750+1200 450+750 450+750 450+750 750+1200 4 4 4 4 4 4 4 4 √ √ 0.007 ±0.008 ±0.008 ±0.008 0.005 0.007 0.005 ±0.008 0.01 ±0.012 ±0.012 ±0.012 0.008 0.01 0.008 ±0.012 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 3-AC 380V 50Hz±5% √ √ Ambient temperature 5~38, ambient humidity <85% √ 2800*2950*3850 2500*2100*2750 2300*2000*3300 2600*2600*3500 2900*2200*2800 3400*2400*3000 2800*2400*2800 3460*2800*3550 11.5 6 7 7.5 9 9 10 13 *The equipment adopts fully enclosed protection, and the protection device is safe and reliable, and should comply with GB/T15760-1995 General Technical Regulations for Safety Protection of Metal Cutting Machine Tools.

*Configure various hydraulic, pneumatic, and water pipe direction markings, mark the operating range of various instruments, and mark the grade of the medium used.Corporate Culture

Corporate Vision

● Supporting China's intelligent manufacturing

Values

● Integrity, Innovation, and Win-Win

Core Mission

● Manufacturing high-quality machine tools in China and building a family-oriented enterprise

Every step of the company's growth and development is inseparable from the strong support and assistance from all sectors of society. Jianha Machine Tool would like to express its sincere gratitude to all its partners and sincerely invites you to join hands and create a more brilliant future together.

Keyword:

Previous:

Next:

Our advantages

R&D capability

Technology innovation as the foundation, continuous product improvement

Exquisite quality stems from meticulous craftsmanship. Jianha Machine Tool continuously conducts technological research and development to optimize product performance and quality, driving product iteration and upgrades. We extensively collect and thoroughly analyze equipment feedback from frontline customers, using it as an important reference for product improvement. Starting from the actual needs of our customers, we focus on enhancing their equipment usage experience and strive to provide them with more competitive, high-quality products.

Productivity

Post-sales integrated into production, addressing pain points proactively

In the pursuit of product quality, Jianha Machine Tool has revolutionized the production concept and constructed the “Post-Retail Production Standard”, which does not mean that there is no after-sales service, but the function of the after-sales department has been transformed so that the after-sales personnel are integrated into the production department. The core of this system lies in the fact that the user pain point problems that may appear in the after-sales process are advanced to the product production stage for screening and solving, so that the products undergo strict quality control and technical optimization before leaving the factory to ensure that each product can bring customers a comfortable experience, and then build a more solid product quality defense line.

Service capability

Full-time technical support, quick troubleshooting

Establish a highly efficient response mechanism, providing 7x24 online technical support. We promise a rapid response within two hours of receiving a customer's after-sales request, offering targeted solutions to troubleshoot problems. Within 48 hours, a professional technical team will be dispatched to the customer's site to quickly locate equipment malfunctions. We strive for speed and efficiency to solve problems for our customers and ensure the smooth operation of their business.

Need help? We're here to help!

To request a quote or find your local dealer, please fill out the form below. If you can't find the product you need.

Contact us anytime 0086-632-5566000 or jianhasale@gmail.com , we will reply to you within 1 hour.

More products